In today’s fast-paced world, robotics has emerged as a game-changer in various industries. One such industry that has witnessed significant advancements is logistics. Robotics in logistics refers to the use of automated systems and robots to streamline and optimize supply chain operations. This article explores the impact of robotics in logistics, focusing on key technologies like Youibot and laser navigation.

The Rise of Robotics in Logistics

Robotics has revolutionized the way goods are handled, stored, and transported within warehouses and distribution centers. With its ability to perform repetitive tasks with precision and efficiency, robots have become an integral part of modern-day logistics operations. By automating processes such as picking, sorting, packing, and inventory management, robotics enhances productivity while reducing human error.

Youibot: A Pioneer in Robotic Solutions

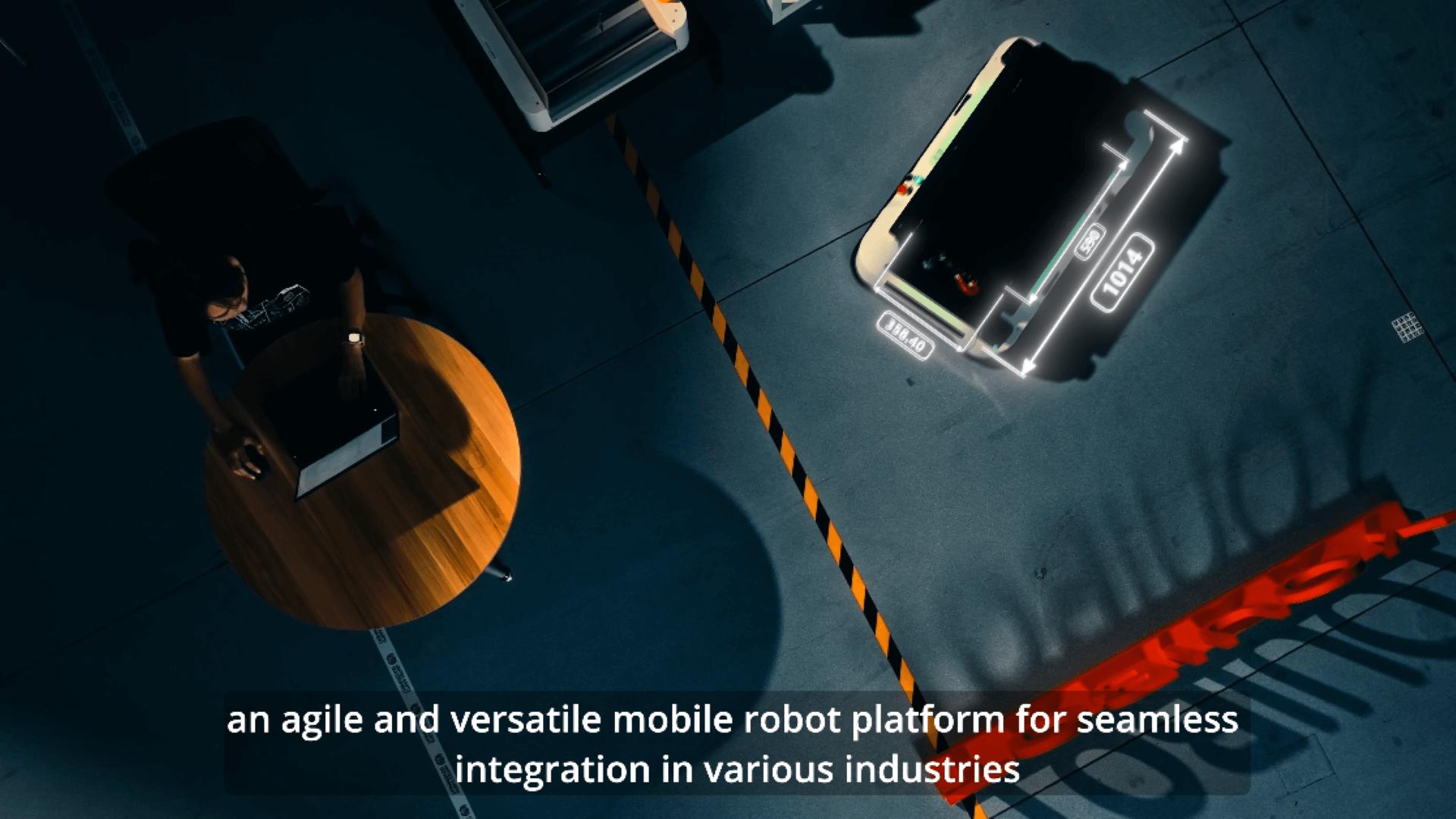

Youibot is at the forefront of providing innovative robotic solutions for logistics applications. Their autonomous mobile robots (AMRs) are designed to navigate complex warehouse environments seamlessly. Equipped with advanced sensors and artificial intelligence algorithms, Youibot‘s AMRs can adapt to dynamic surroundings while ensuring safe collaboration with human workers.

These intelligent robots can efficiently transport goods from one location to another within a facility without requiring any physical infrastructure modifications. They can also be integrated into existing warehouse management systems (WMS), enabling real-time tracking of inventory movement and optimizing order fulfillment processes.

Laser Navigation: Precision at Its Best

laser navigation technology plays a crucial role in enhancing the capabilities of robotics in logistics. It enables robots to accurately map their surroundings using laser scanners or LiDAR (Light Detection And Ranging) sensors.

By creating detailed maps of their environment, robots equipped with laser navigation can navigate through narrow aisles, avoid obstacles, and optimize their paths for maximum efficiency. This technology ensures precise positioning and enables robots to perform tasks with minimal human intervention.

Furthermore, laser navigation allows robots to adapt to changes in the environment in real-time. They can detect new obstacles or modifications within the warehouse layout and adjust their routes accordingly. This flexibility enhances operational agility and reduces downtime caused by manual reconfiguration of fixed infrastructure.

The Future of Robotics in Logistics

Robotics in logistics is poised to reshape the supply chain landscape further. As technology continues to advance, we can expect more sophisticated robotic solutions that integrate seamlessly with existing systems and processes.

The benefits offered by robotics in logistics are undeniable – increased productivity, improved accuracy, reduced labor costs, enhanced safety measures, and faster order fulfillment. By leveraging these technologies effectively, businesses can gain a competitive edge while meeting evolving customer demands.

In conclusion, robotics has revolutionized logistics operations by introducing automation into various aspects of the supply chain. With companies like Youibot leading the way with innovative solutions such as autonomous mobile robots and laser navigation technology, we are witnessing a transformation that promises greater efficiency and optimization within warehouses worldwide.